Laser Cutting

Laser Cutting

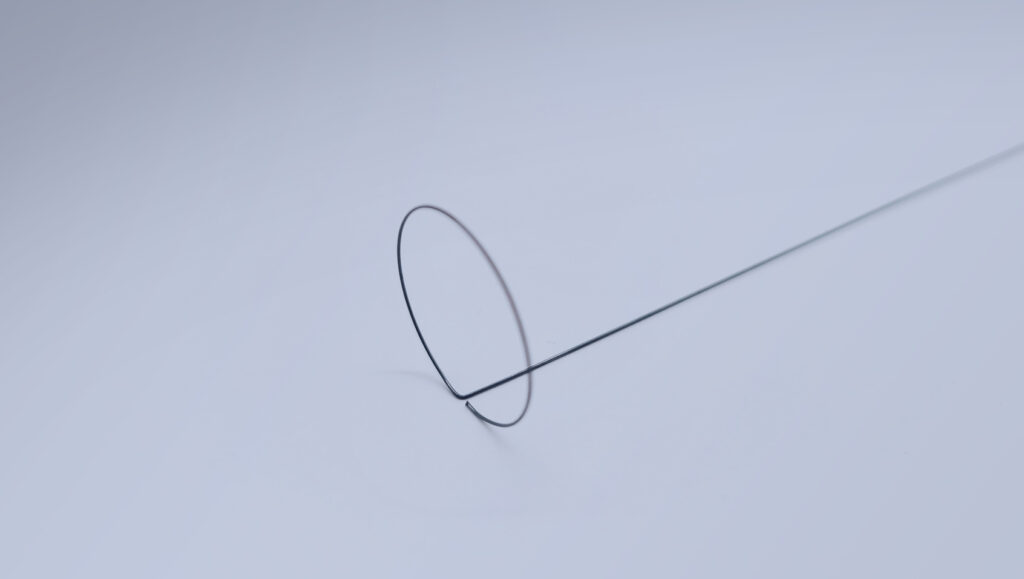

Tube Cutting

Tube cutting uses a laser beam delivery positioned over an x-y-rotary motion system. Additional axes are available for tilt, focus, and off-center cutting. Advanced energy-management techniques produce a clean, smooth edge.

Strut Width

Material Thickness

Diameter Range

Beam Kerf Width

25 microns (0.001″) – 1.5 mm (0.06″)

0.1 mm (0.004″) – 25 mm (1″)

15 microns (0.0006″) – 100 microns (0.004″)

25 microns (0.001″) typ

Strut Width

0.015mm (0.0006”) and up ± 5 microns (0.0002″) typ

Material Thickness

25 microns (0.001″) – 1.5 mm (0.06″)

Diameter Range

0.1 mm (0.004″) – 25 mm (1″)

Beam Kerf Width

15 microns (0.0006″) – 100 microns (0.004″)

25 microns (0.001″) typ

Sheet Cutting

Sheet cutting can accommodate fairly large sheets.

Strut Width

Material Thickness

Beam Kerf Width

0.015mm (0.0006”) and up ± 5 microns (0.0002″) typ

25 microns (0.001″) – 1.5 mm (0.06″)

15 microns (0.0006″) – 100 microns (0.004″)

25 microns (0.001″) typ

Strut Width

0.015mm (0.0006”) and up ± 5 microns (0.0002″) typ

Material Thickness

25 microns (0.001″) – 1.5 mm (0.06″)

Beam Kerf Width

15 microns (0.0006″) – 100 microns (0.004″)

25 microns (0.001″) typ

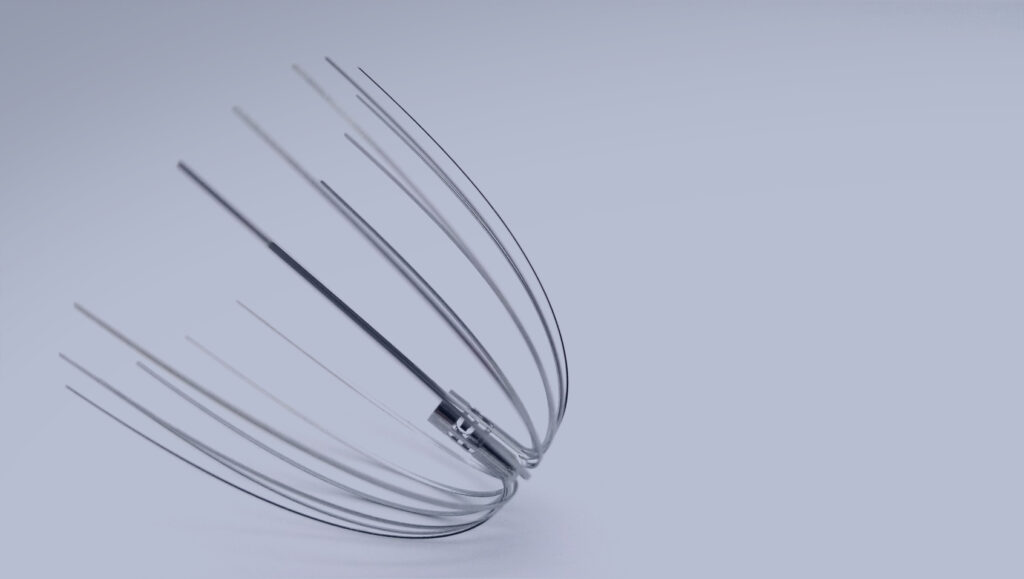

Laser Welding

Laser-welding includes all varieties of weld geometries and dissimilar metals.

Weld Geometries

Applications

Lap weld, butt weld, angle weld, wire/tube/sheet

Occluders, pull-ring assemblies, closure, laser-cut navigation shaft, etc.

Weld Geometries

Lap weld, butt weld, angle weld, wire/tube/sheet

Applications

Occluders, pull-ring assemblies, closure, laser-cut navigation shaft, etc.

Laser Marking

Marking Material

Stainless steels, L605, MP35N, Nitinol, Mg-alloys, Zn-alloys, Ti-alloys, Ta, etc.

Nitinol Marking Colors

Oxide free Surface:Yellow-Brown, Blue-Purple, Blue-Gray

Oxide Surface:Silver White

Stainless Steel Marking Colors

Black, Dark Brown, Dark Grey

Nitinol Marking Colors Stainless Steel Marking Colors

Stainless steels, L605, MP35N, Nitinol, Mg-alloys, Zn-alloys, Ti-alloys, Ta, etc.

Oxide free Surface:Yellow-Brown, Blue-Purple, Blue-Gray

Oxide Surface:Silver White

Black, Dark Brown, Dark Grey

Other Capabilities

Lumenous provides expert precision components and premium finishing to the medical device and precision instrument industries worldwide.

Experience contract manufacturing with technological mastery.