Laser Cutting

Laser Cutting

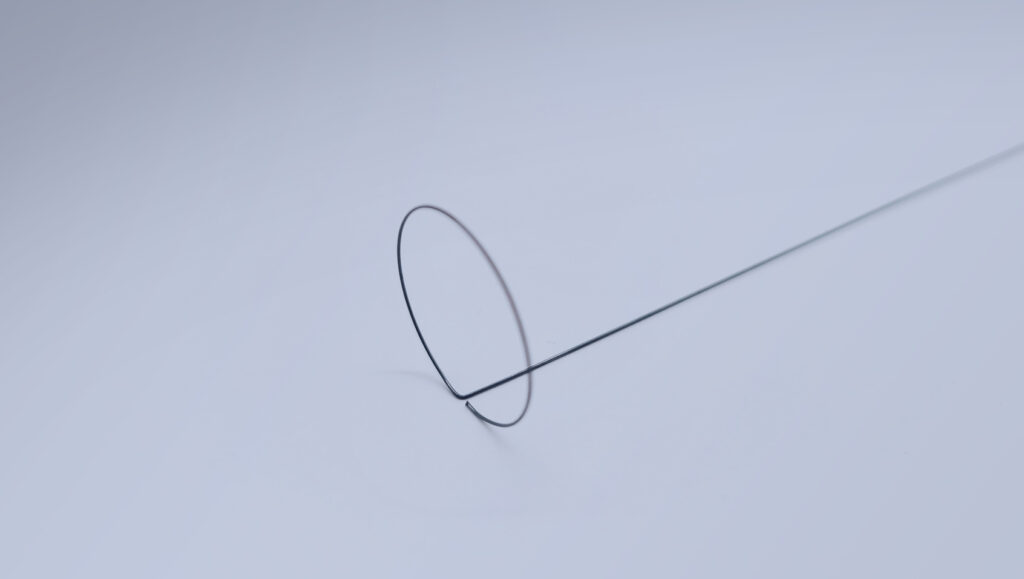

Tube Cutting

Tube cutting uses a laser beam delivery positioned over an x-y-rotary motion system. Additional axes are available for tilt, focus, and off-center cutting. Advanced energy-management techniques produce a clean, smooth edge.

Strut Width

Material Thickness

Diameter Range

Beam Kerf Width

25 microns (0.001″) – 1.5 mm (0.06″)

0.1 mm (0.004″) – 25 mm (1″)

15 microns (0.0006″) – 100 microns (0.004″)

25 microns (0.001″) typ

Strut Width

0.015mm (0.0006”) and up ± 5 microns (0.0002″) typ

Material Thickness

25 microns (0.001″) – 1.5 mm (0.06″)

Diameter Range

0.1 mm (0.004″) – 25 mm (1″)

Beam Kerf Width

15 microns (0.0006″) – 100 microns (0.004″)

25 microns (0.001″) typ

Sheet Cutting

Sheet cutting can accommodate fairly large sheets.

Strut Width

Material Thickness

Beam Kerf Width

0.015mm (0.0006”) and up ± 5 microns (0.0002″) typ

25 microns (0.001″) – 1.5 mm (0.06″)

15 microns (0.0006″) – 100 microns (0.004″)

25 microns (0.001″) typ

Strut Width

0.015mm (0.0006”) and up ± 5 microns (0.0002″) typ

Material Thickness

25 microns (0.001″) – 1.5 mm (0.06″)

Beam Kerf Width

15 microns (0.0006″) – 100 microns (0.004″)

25 microns (0.001″) typ

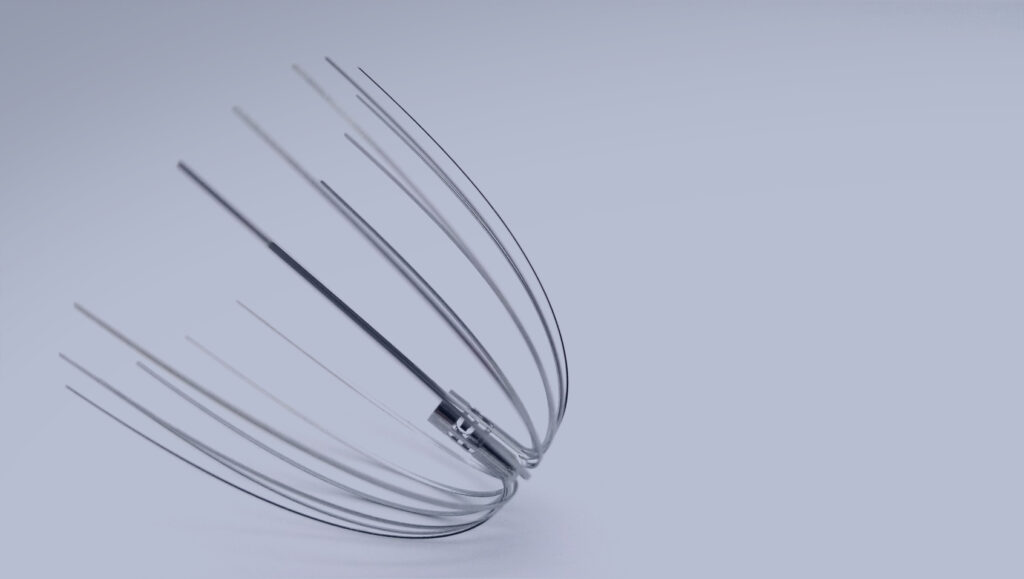

Laser Welding

Laser-welding includes all varieties of weld geometries and dissimilar metals.

Lap weld, butt weld, angle weld, wire/tube/sheet

Occluders, pull-ring assemblies, closure, laser-cut navigation shaft, etc.

Weld Geometries

Lap weld, butt weld, angle weld, wire/tube/sheet

Applications

Occluders, pull-ring assemblies, closure, laser-cut navigation shaft, etc.

Laser Marking

Marking Material

Stainless steels, L605, MP35N, Nitinol, Mg-alloys, Zn-alloys, Ti-alloys, Ta, etc.

Nitinol Marking Colors

Oxide free Surface:Yellow-Brown, Blue-Purple, Blue-Gray

Oxide Surface:Silver White

Stainless Steel Marking Colors

Black, Dark Brown, Dark Grey

Nitinol Marking Colors Stainless Steel Marking Colors

Stainless steels, L605, MP35N, Nitinol, Mg-alloys, Zn-alloys, Ti-alloys, Ta, etc.

Oxide free Surface:Yellow-Brown, Blue-Purple, Blue-Gray

Oxide Surface:Silver White

Black, Dark Brown, Dark Grey

Other Capabilities

Lumenous provides expert precision components and premium finishing to the precision instrument industries worldwide.

Experience contract manufacturing with technological mastery.